Products

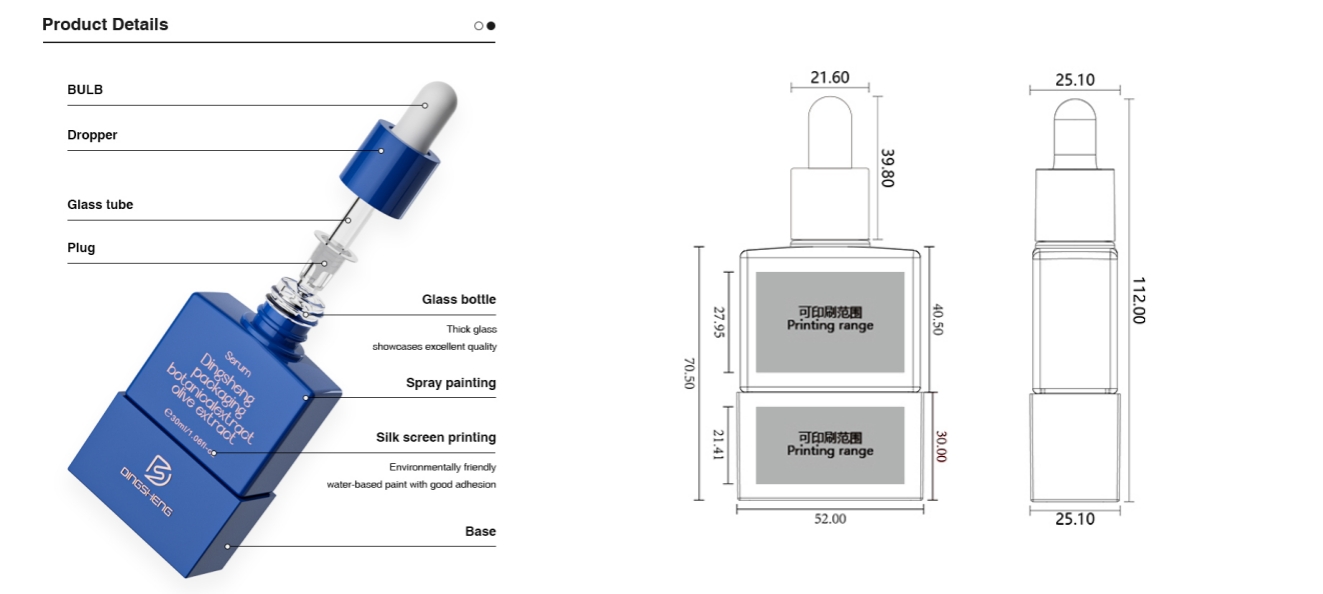

Designed for serums and essential oils, this 30ml square glass dropper bottle features a stable cube structure with a heavy-wall base.

Produced in a Class 100,000 cleanroom, the high-white glass body ensures chemical inertness and full compatibility with active formulas. The bottle’s flat panels allow for precise edge-to-edge silk screen printing and hot stamping without curvature distortion.

As a direct manufacturer, Dingsheng provides comprehensive OEM services, including Pantone color matching and strict quality inspection for private label orders.

Item No :

DS-2075Order(MOQ) :

10000Suitable for :

Serum,Essential oilVolume :

30mlMaterial :

GlassPrinting :

Silk Screen Printing / Hot StampingCustom :

Color / Surface Handing / Private Mold / Bottle / Cap Colored or Decoration / PrintingLead time :

35-45 daysSample :

7-10 daysQuailty Control :

100% Inspection Before PackingSurface Handing :

Silk Screen PrintingCube Glass Dropper Bottle with Thick Bottom for Cosmetic Packaging

Features

Square Profile: Four flat panels ensure shelf stability and clear branding display.

Square Profile: Four flat panels ensure shelf stability and clear branding display.

Heavy-Wall Base: Thickened glass bottom lowers center of gravity for stability.

Heavy-Wall Base: Thickened glass bottom lowers center of gravity for stability.

Distortion-Free Printing: Flat surfaces enable precise edge-to-edge silk screen printing.

Distortion-Free Printing: Flat surfaces enable precise edge-to-edge silk screen printing.

Chemical Inertness: High-white glass ensures compatibility with active ingredients.

Chemical Inertness: High-white glass ensures compatibility with active ingredients.

Precision Dosage: Includes a calibrated glass pipette for controlled dispensing.

Precision Dosage: Includes a calibrated glass pipette for controlled dispensing.

Applications

Concentrated Serums: Standard 30ml capacity for high-value facial serums.

Concentrated Serums: Standard 30ml capacity for high-value facial serums.

Essential & Face Oils: Protects sensitive botanical extracts from oxidation.

Essential & Face Oils: Protects sensitive botanical extracts from oxidation.

Hair Treatment Oils: Handles viscous formulas via wide-stem pipettes.

Hair Treatment Oils: Handles viscous formulas via wide-stem pipettes.

Cosmeceuticals: Meets safety standards for clinical skincare brands.

Cosmeceuticals: Meets safety standards for clinical skincare brands.

Specifications

| Model Number | DS-2075 |

| Product Type | Square Heavy-Wall Glass Dropper Bottle |

| Capacity | 30ml |

| Dimensions | 52mm (W) × 25.1mm (D) × 112mm (H) |

| Material | High White Flint Glass (Body) + Glass Pipette |

| Components | Bottle, Dropper Collar, Bulb, Wiper Plug |

| Decoration | Silk Screen, Hot Stamping, Spray Coating, Frosting |

| MOQ | 10,000 PCS |

| Lead Time | 35-45 Days (Sample: 7-10 Days) |

Why Choose Us

1. 100% Raw Material Inspection: Only high-white, impurity-free glass sand is used.

2. Automatic Ultrasonic Washing: Every glass bottle undergoes multi-stage ultrasonic cleaning and drying before entering the decoration line to ensure zero dust contamination.

3. Vacuum Leak Testing: We perform random vacuum negative pressure tests on every batch to guarantee the pump and bottle fit perfectly (No leakage).

4. Visual & Functional Check: 100% full inspection on the assembly line for scratches, printing defects, or pump malfunctions.

5. Certifications: ISO 9001:2015 Quality Management System certified.

Sitemap Blog Xml Privacy Policy

Copyright @2024 Dingsheng (Guangdong) Glass Technology Co.Ltd. All Rights Reserved.  Network Supported

Network Supported