Products

Wholesale Full Series Cosmetic Glass Packaging Set | 30g-150ml Bottles & Jars for Toner, Lotion, Cream

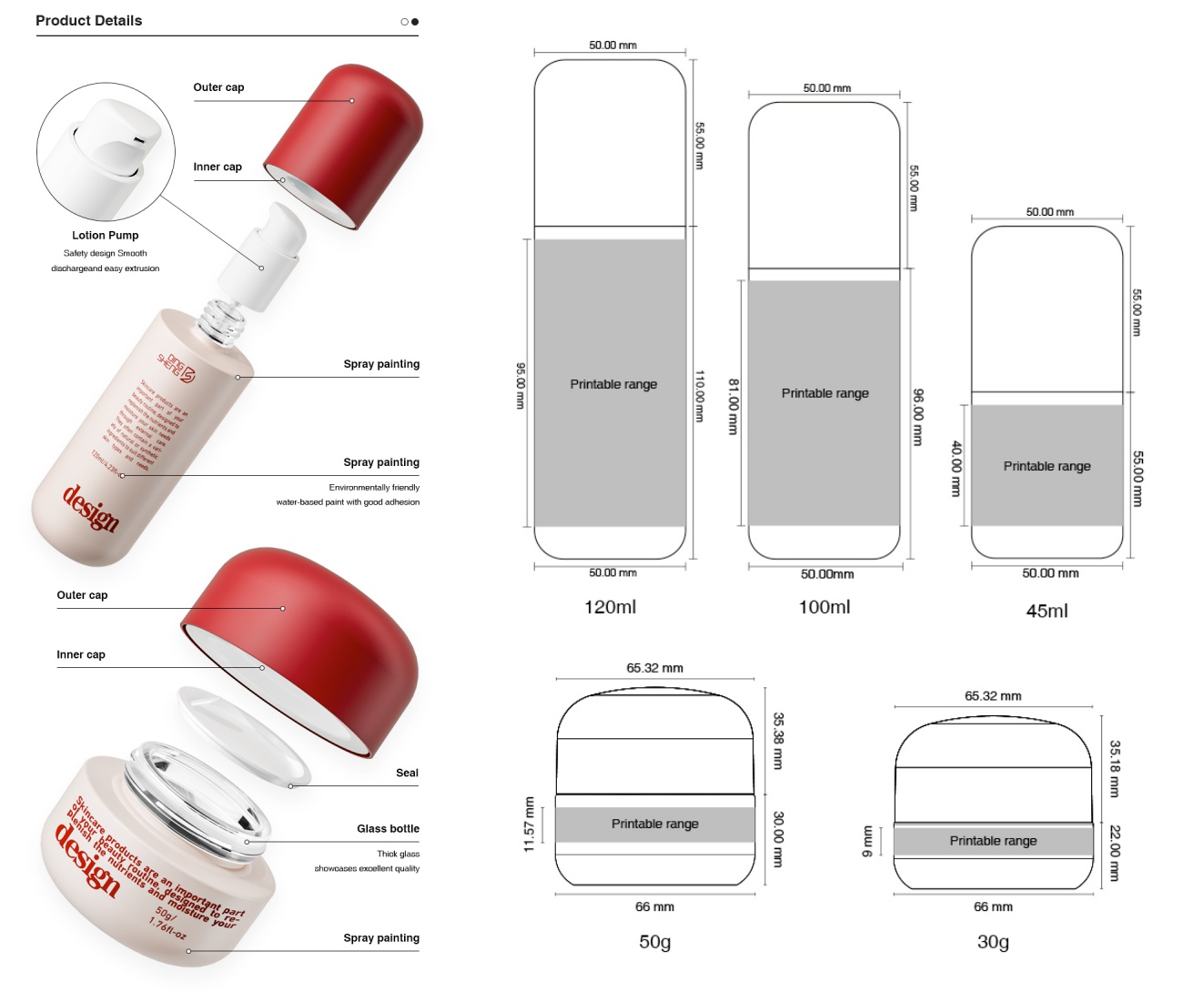

This glass packaging series offers a complete solution for skincare product lines, ranging from 30g jars to 150ml bottles. The set includes containers suitable for toner, serum, lotion, and face cream.

Manufactured in Dingsheng’s Class 100,000 Cleanroom, the bottles feature heavy-wall glass construction. We provide custom surface treatments, including color spraying, screen printing, and hot stamping for private label orders.

Item No :

DS-0062BOrder(MOQ) :

10000Suitable for :

Toner,Lotion,Serum,Essential oil,CreamVolume :

150ml/120ml/100ml/45ml/50g/30gMaterial :

GlassPrinting :

Spray PaintingCustom :

Color/Volume/Surface Handing/Private mold/Bottle/Cap Colored or Decoration/PrintingLead time :

25-35 daysSample :

AvailableQuailty Control :

100% Inspection Before PackingSurface Handing :

Silk Screen PrintingCustom Printed Glass Cosmetic Bottle Series for Beauty Brands

Features

Full Series Coverage: From 30g jars to 150ml bottles.

Full Series Coverage: From 30g jars to 150ml bottles.

Heavy-Wall Glass: Premium tactile feel and high transparency.

Heavy-Wall Glass: Premium tactile feel and high transparency.

Unified Design: Consistent cylindrical aesthetic for branding.

Unified Design: Consistent cylindrical aesthetic for branding.

Class 100,000 Cleanroom: Pharmaceutical-grade production.

Class 100,000 Cleanroom: Pharmaceutical-grade production.

Custom Decoration: Spraying, Silk Screen, Hot Stamping.

Custom Decoration: Spraying, Silk Screen, Hot Stamping.

Strict QC: Ultrasonic washing & ISO-9001 certified.

Strict QC: Ultrasonic washing & ISO-9001 certified.

Applications

150ml / 120ml / 100ml: Toner, Essence Water, Lotion.

150ml / 120ml / 100ml: Toner, Essence Water, Lotion.

45ml: Concentrated Serum, Facial Oil, Hair Essence.

45ml: Concentrated Serum, Facial Oil, Hair Essence.

50g / 30g Jars: Day Cream, Night Mask, Eye Cream.

50g / 30g Jars: Day Cream, Night Mask, Eye Cream.

Versatile: Compatible with Pumps, Sprays, and Droppers.

Versatile: Compatible with Pumps, Sprays, and Droppers.

Specifications

| Model Number | DS-0062B |

| Product Series | Luxury Cylindrical Glass Skincare Set |

| Capacity Options | Bottles: 150ml, 120ml, 100ml, 45ml Jars: 50g, 30g |

| Body Material | High White Glass (Thick-wall construction) |

| Accessories Material | PP / ABS / MS / Acrylic (Pump, Cap, Disc) |

| Surface Decoration | Silk Screen Printing, Hot Stamping, Spray Painting, Frosting |

| Closure Options | Lotion Pump, Mist Sprayer, Dropper, Screw Cap |

| HS Code | 7010909000 |

| Production Environment | Class 100,000 Cleanroom (GMP Standard) |

| Quality Certification | ISO 9001:2015 |

| MOQ | 10,000 PCS (Negotiable for first order) |

| Lead Time | 25-45 Days after sample confirmation |

Why Choose Us

1. 100% Raw Material Inspection: Only high-white, impurity-free glass sand is used.

2. Automatic Ultrasonic Washing: Every glass bottle undergoes multi-stage ultrasonic cleaning and drying before entering the decoration line to ensure zero dust contamination.

3. Vacuum Leak Testing: We perform random vacuum negative pressure tests on every batch to guarantee the pump and bottle fit perfectly (No leakage).

4. Visual & Functional Check: 100% full inspection on the assembly line for scratches, printing defects, or pump malfunctions.

5. Certifications: ISO 9001:2015 Quality Management System certified.

Sitemap Blog Xml Privacy Policy

Copyright @2024 Dingsheng (Guangdong) Glass Technology Co.Ltd. All Rights Reserved.  Network Supported

Network Supported